The world of boxing has always been dynamic, evolving with time and adjusting to the ever-changing preferences of its consumers. As boxing equipment manufacturers, it is crucial to understand and adapt to these consumer preferences to stay relevant in a competitive market. In this article, we will explore the key aspects of adapting to consumer preferences in boxing equipment manufacturing, focusing on quality, innovation, customization, sustainability, comfort, durability, branding, consumer feedback, market expansion, and the future landscape of the industry.

Boxing enthusiasts invest in high-quality boxing gear to maximize their performance, enhance safety, and express their individuality. Manufacturers must closely follow consumer preferences to deliver products that cater to their desires. By analyzing current trends and understanding customer needs, boxing equipment manufacturers can create superior products and gain a competitive edge.

Understanding Consumer Preferences

Consumer preferences in boxing equipment are influenced by various factors. These factors include performance, style, durability, affordability, and brand reputation. By understanding the importance of each factor, manufacturers can make informed decisions to meet consumer expectations.

Factors influencing consumer choices

When consumers shop for boxing equipment, they consider a range of factors. Performance is a top consideration, as fighters expect gear that enhances their technique and provides adequate protection. Style and aesthetics also play a significant role, as individuals seek gear that aligns with their identity and taste. Durability is crucial, as boxing is a physically demanding sport that places substantial strain on equipment. Additionally, affordability, brand reputation, and endorsements from professional fighters can heavily sway consumer choices.

Current trends in boxing equipment

The boxing equipment industry has witnessed several trends in recent years. One notable trend is the increasing demand for equipment that strikes a balance between professional-grade quality and affordable pricing. Consumers are seeking durable and reliable gear without breaking the bank. Another trend is the rise of women’s boxing, leading to a demand for gear tailored specifically for female fighters. Furthermore, there has been a surge in demand for eco-friendly and sustainable boxing equipment, driven by consumers’ growing environmental consciousness.

Quality vs. Price: Striking the Right Balance

In boxing, quality is of utmost importance. Whether it’s gloves, headgear, or punching bags, fighters rely on their gear to protect them from injuries and enhance their performance. However, quality should not come at the expense of affordability. Manufacturers must strike the right balance between price and quality to attract customers from diverse backgrounds.

To achieve this balance, manufacturers can optimize their production processes, leverage economies of scale, and find cost-effective raw materials without compromising on quality. By streamlining operations and reducing overhead costs, savings can be passed on to customers without sacrificing the integrity of the equipment.

The Role of Innovation

Innovative approaches breathe life into any industry, and boxing equipment manufacturing is no exception. By incorporating new technologies, manufacturers can create gear that pushes boundaries and surpasses consumer expectations.

Incorporating new technologies in boxing equipment

Advancements in technology have opened up exciting possibilities for boxing equipment. Manufacturers can integrate cutting-edge materials, smart functionalities, and advanced design elements to revolutionize the way fighters train and compete.

One example of technology integration is the use of high-performance materials like carbon fiber and impact-absorbing foams. These materials offer superior protection while keeping the gear lightweight and flexible. Additionally, manufacturers have started incorporating sensor technology into gloves, allowing fighters to track punch accuracy, speed, and force, providing valuable data for training purposes.

Another innovative approach is the use of 3D printing. This technology enables the creation of custom-fit equipment tailored to an individual’s unique body measurements and preferences while reducing production waste. Customized mouthguards, headgear, and even boxing gloves can now be manufactured using 3D printing techniques.

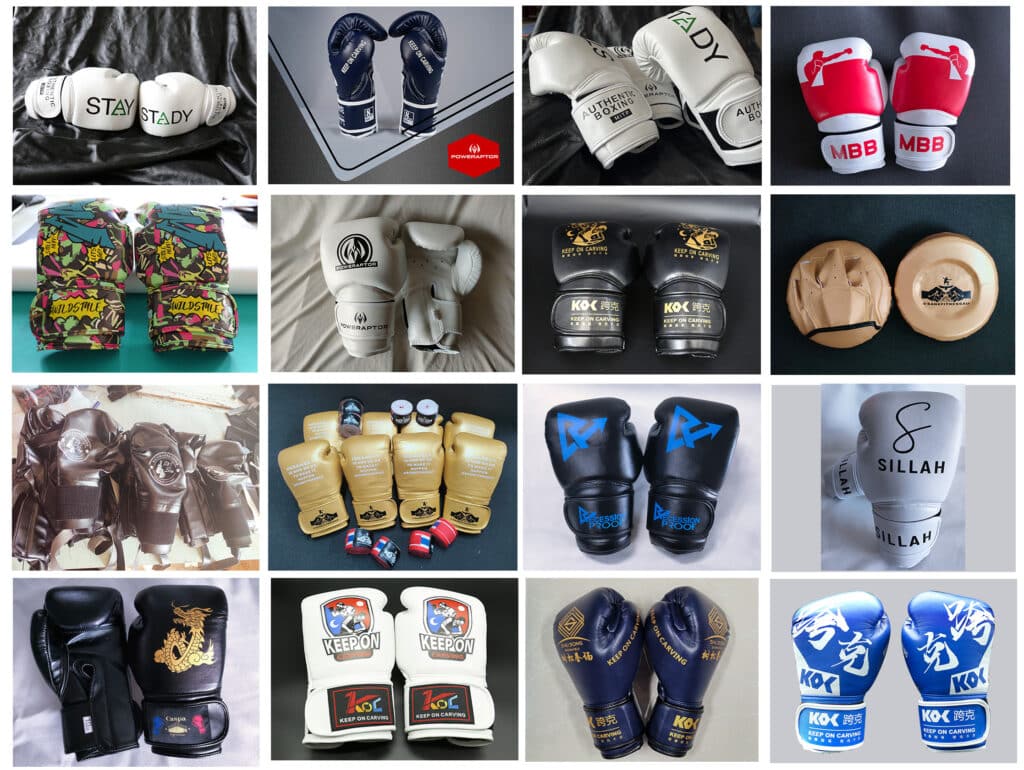

Customization and Personalization

In today’s market, consumers seek products that resonate with their individuality. This desire for personalization has extended to boxing equipment, leading to a growing demand for customized gear. Manufacturers can capitalize on this trend by offering options for personalization, allowing fighters to express their unique styles and preferences.

Customization can involve selecting colors, materials, and designs, as well as adding personalized embroidery or logos. By providing a range of choices, manufacturers empower consumers to create gear that reflects their personality and boosts their confidence in the ring.

Moreover, customization extends beyond aesthetics. Some manufacturers offer custom-fit equipment, ensuring a snug and comfortable fit for each fighter. Custom-fit gloves, headgear, and mouthguards not only enhance performance but also reduce the risk of injuries caused by ill-fitting gear. By offering customization options, manufacturers can forge deeper connections with customers and establish brand loyalty.

Benefits of customized equipment

Customized boxing equipment offers several benefits that resonate with fighters and enthusiasts alike. Firstly, it provides a sense of exclusivity. Custom gear allows fighters to stand out from the crowd and assert their individuality. Furthermore, personalized equipment can boost fighters’ self-confidence, enhancing their overall performance inside the ring.

Additionally, customized gear ensures a better fit. Ill-fitting equipment can hamper a fighter’s mobility and comfort, negatively impacting their performance. Custom-fit gear conforms perfectly to a fighter’s body, optimizing their movements and providing the highest level of protection. By offering customization options, manufacturers can address individual needs and deliver gear that adapts to each fighter’s unique style and requirements.

Sustainable and Ethical Boxing Equipment Manufacturing

In recent years, sustainability has emerged as a critical concern across industries, and boxing equipment manufacturing is no exception. Consumers are increasingly conscious of environmental impact and seek products that align with their values. To thrive in this new landscape, manufacturers must adopt sustainable and ethical manufacturing practices.

Consumers’ increasing focus on sustainability

Modern consumers are aware of the environmental consequences associated with production and consumption. They demand products that minimize waste, use eco-friendly materials, and adhere to responsible manufacturing processes. This trend has prompted boxing equipment manufacturers to take significant steps towards sustainability.

By utilizing recycled materials, reducing greenhouse gas emissions, optimizing energy consumption, and implementing efficient waste management, manufacturers can create products with a minimal environmental footprint. These sustainable practices not only appeal to eco-conscious consumers but also contribute to the long-term viability of the industry.

Ethical manufacturing practices in the industry

Apart from environmental considerations, consumers also value ethical manufacturing practices. They expect companies to prioritize fair labor conditions, workers’ rights, and supply chain transparency. Boxing equipment manufacturers must engage in responsible sourcing, ensuring that the materials used in their products are ethically obtained and that workers involved in the manufacturing process are treated fairly.

By partnering with suppliers who adhere to ethical standards, conducting regular audits, and providing safe working conditions, manufacturers can assure consumers that their products are ethically produced. This commitment to ethical manufacturing not only strengthens brand reputation but also fosters trust among customers.

The Importance of Comfort in Boxing Equipment Manufacturing

Comfort plays a pivotal role in boxing equipment. Fighters spend hours training and competing, relying on gear that allows them to perform at their best while minimizing discomfort and distractions. Therefore, manufacturers must prioritize comfort in their designs.

Ergonomics and comfort in boxing equipment

Ergonomics refers to the study of how equipment design can optimize human performance and well-being. In the context of boxing equipment, ergonomics focuses on creating gear that fits well, reduces strain on the body, and allows for natural movements.

Manufacturers achieve ergonomic designs by considering factors such as glove shape, weight distribution, padding density, and breathability. Gloves with pre-curved designs and moisture-wicking materials can improve hand comfort and reduce the risk of overheating, while headgear with adjustable straps and breathable linings enhances overall comfort during training and fights.

Design elements for enhanced comfort

Boxing equipment manufacturers continually innovate to enhance comfort. For example, some gloves incorporate multi-layered padding, which not only cushions impact but also helps distribute force evenly, reducing the risk of injuries. Similarly, headgear with foam cushioning and adjustable chin straps offer a secure and comfortable fit.

In addition to ergonomic design, manufacturers also focus on using materials that offer superior comfort. Breathable fabrics, moisture-wicking liners, and foam padding that molds to the wearer’s body all contribute to enhanced comfort levels. By prioritizing comfort, manufacturers can provide fighters with equipment that allows them to focus solely on their performance, without distractions from discomfort or poorly fitting gear.

Durability and Longevity of Boxing Equipment Manufacturing

Durability is a key consideration for boxing equipment. Fighters rely on gear that can withstand intense training sessions, sparring, and fights. Manufacturers must prioritize durability by employing robust construction techniques and selecting high-quality materials.

Boxing equipment’s lifespan and durability expectations

Boxing equipment endures significant wear and tear, subjected to countless punches, impacts, and physical strain. Fighters rely on their gear to withstand the test of time, providing reliable protection over extended periods.

Manufacturers should aim to produce equipment that has a reasonable lifespan and meets durability expectations. Gloves, for instance, should maintain their structural integrity, padding density, and protection levels even after prolonged use. Similarly, punching bags and focus mitts should resist tearing and fraying, ensuring longevity and optimal performance.

Materials and construction techniques

To ensure durability, manufacturers carefully select materials known for their resilience. Genuine leather and synthetic materials like high-quality polyurethane (PU) or polyvinyl chloride (PVC) offer excellent durability and resistance to wear and tear. These materials withstand repeated impacts and can withstand the rigors of regular training.

In addition to material selection, manufacturers employ construction techniques that enhance durability. Reinforced stitching, double-layered padding, and reinforced seams all contribute to the longevity of boxing equipment. By focusing on durability, manufacturers build trust and loyalty among fighters who rely on gear that withstands their toughest workouts and fights.

The Future of Boxing Equipment Manufacturing

The landscape of boxing equipment manufacturing continues to evolve, driven by technological advancements, changing consumer preferences, and emerging trends. Manufacturers must stay ahead of the curve by embracing innovation and anticipating future developments.

Anticipated developments and trends

Several developments are likely to shape the future of boxing equipment manufacturing. The integration of wearable technology, such as smart sensors and biometric trackers, holds promise for enhanced performance monitoring and data-driven training strategies.

The use of sustainable and eco-friendly materials will become more prevalent as environmental concerns continue to influence consumer choices. Manufacturers will strive to develop gear that is both high-performance and environmentally responsible.

Moreover, the personalization trend is expected to deepen, with manufacturers offering even more options for customization and tailored fit. Advancements in 3D printing technology may enable on-demand production of custom-fit equipment at lower costs and reduced lead times.

Another area of growth is in digital platforms and e-commerce. Manufacturers will increasingly leverage online platforms for direct-to-consumer sales, allowing them to reach a wider audience and offer a seamless purchasing experience.

Manufacturers will also continue to invest in research and development to create new and innovative designs that prioritize comfort, durability, and protection. Collaborations with professional athletes and coaches will help drive these advancements, ensuring that the gear meets the specific needs of elite fighters.

Lastly, in response to the growing popularity of combat sports like MMA, manufacturers will expand their product lines to cater to the unique requirements of these disciplines. This expansion will involve designing gear that offers the necessary protection, flexibility, and functionality for a variety of combat techniques.